Kubunjineli bemijelo yamanzi, inkqubo yokukhupha amanzi ibaluleke kakhulu. Inethi yokukhupha amanzi edibeneyo enamacala amathathu sisixhobo sokukhupha amanzi esisetyenziswa kakhulu kubunjineli bemijelo yamanzi. Ngoko ke, zithini izicelo zayo kwimijelo yamanzi?

I. Iimpawu zobugcisa zenethi yokukhupha amanzi edityanisiweyo enamacala amathathu

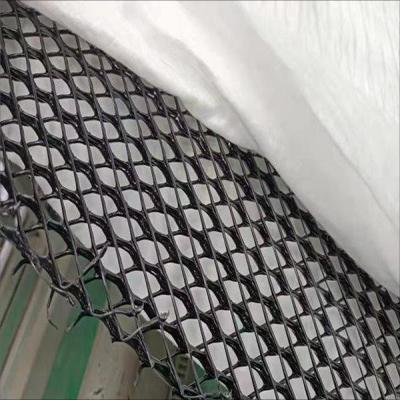

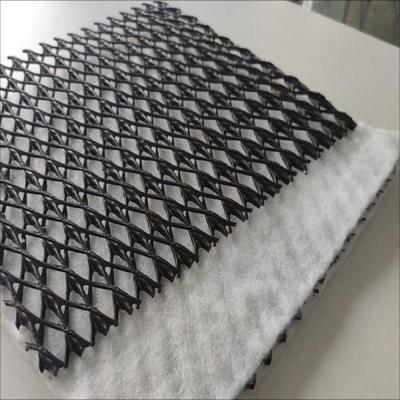

Inethi yokukhupha amanzi edityanisiweyo enamacala amathathu yindibaniselwano yesiseko seplastiki enemilinganiselo emithathu eyenziwe nge-polyethylene ephezulu (i-HDPE) kunye ne-geotextile ejikelezileyo enamacala amabini. Ulwakhiwo lwayo oluphambili ngumjelo wokukhupha amanzi owenziwe ziimbambo ezithe nkqo kunye neembambo ezixhasayo eziphezulu nezisezantsi ukuze zenze inkqubo yokuxhasa ezinzileyo. Ke ngoko, ineenzuzo ezintathu eziphambili zobugcisa:

1. Umthamo wokukhupha amanzi ngokufanelekileyo: Ukuvuleka kwamanzi kungafikelela kwi-2500m/d, nto leyo elingana nomphumo wokukhupha amanzi womaleko wegrabile onobukhulu obuyimitha e-1, kwaye ungakhupha amanzi amdaka ngokukhawuleza kwitonela.

2. Ukumelana noxinzelelo oluphezulu: Ingamelana nomthwalo ophantsi koxinzelelo oluphezulu we-3000kPa ixesha elide, ubukhulu be-mesh core yi-5-8mm, kwaye amandla okutsalwa yi-≥36.5kN/m, okuqinisekisa ukusebenza okuzinzileyo phantsi kweemeko ezinzima zejoloji.

3. Umsebenzi wokhuseleko olupheleleyo: Unemisebenzi yokulwa nokuhluza, ukungena komoya, kunye nemisebenzi yokuqinisa isiseko, okwenza inkqubo yokhuselo edibeneyo "yokukhusela ukuhluza-ukukhupha amanzi".

II. Iimeko ezine eziphambili zokusetyenziswa kubunjineli bemigudu

1. Umaleko wokukhupha amanzi emva kwelayini

Uxinzelelo lwamanzi luvela lula ngenxa yokuqokelelwa kwamanzi angaphantsi komhlaba emva kwelayini yomsele, nto leyo ekhokelela ekuvuzeni kwamanzi aze awonakalise isakhiwo. Inethi yokukhupha amanzi edibeneyo enamacala amathathu ibekwa phakathi kwelayini kunye nelitye elijikelezileyo ukuze kwenziwe umjelo wokukhupha amanzi omde ukuze ukhokele ukuvuza kwentaba kumsele osecaleni ukuze kukhutshwe amanzi.

2. Inkqubo yokukhupha amanzi e-arch eguqulweyo

I-arch eguqulweyo ithambekele ekuguqukeni kweqhwa ngenxa yokuqokelelwa kwamanzi. Inethi yokukhupha amanzi edityanisiweyo enamacala amathathu isetyenziswa kunye nomaleko wegrabile ukukhuculula amanzi angaphantsi komhlaba ngokukhawuleza. Ulwakhiwo lwayo olunamacala amathathu lunokuthintela ukunyuka kwamanzi e-capillary kwaye luthintele umonakalo weqhwa lasebusika.

3. Umaleko wokukhupha amanzi eludongeni olusecaleni

Kwitonela enelitye elijikelezileyo elibuthathaka, ukuvuza kwamanzi eludongeni olusecaleni kunokubangela ukuba isakhiwo esixhasayo singazinzi. Njengomaleko wokukhupha amanzi eludongeni olusecaleni, inethi yokukhupha amanzi edibeneyo enamacala amathathu ayinakukhupha amanzi aphumayo kuphela, kodwa ikwanciphisa ukuguquguquka kwelitye elijikelezileyo ngamandla alo aphezulu okuxinana. Idatha yovavanyo ibonisa ukuba amandla ayo okucheba aphezulu ngama-40% kunezixhobo zemveli, ezinokuqinisekisa uzinzo lodonga olusecaleni.

4. Umaleko wotshintsho lwesango lokuhambisa amanzi kwi-tunnel

Isango letonela linokudilika ngenxa yokungena kwamanzi angaphezulu komhlaba. Inetha yokukhupha amanzi edibeneyo enamacala amathathu ibekwe emva kwengaphakathi lesango letonela ukuze yenze umaleko wokuguqula amanzi ukuze ukhokele amanzi angaphezulu angene emseleni wokukhupha amanzi. Ukumelana kwayo nokugqwala kunokumelana nokukhukuliseka kwamanzi angaphantsi komhlaba ane-asidi kwaye kuqinisekise uzinzo lwexesha elide.

III. Iindawo zokwakha kunye nolawulo lomgangatho

1. Ulawulo lwendlela yokubeka: Ubude bendlela yomqulu wezinto kufuneka bube ngqo kwi-axis yetonela ukuqinisekisa ukuba umjelo wokukhupha amanzi uhambelana nendlela yokuhamba kwamanzi.

2. Unyango oludibeneyo: Sebenzisa iteknoloji ye-buckle okanye ye-welding ukulungisa, ubude bokugqithana buyi-≥15cm, kwaye sebenzisa izikhonkwane ezimile okwe-U okanye iibhanti ze-polymer ukudibanisa rhoqo nge-0.3m.

3. Ukukhusela i-backfill: I-backfill kufuneka igqitywe zingadlulanga iiyure ezingama-48 emva kokubekwa, ubukhulu obukhulu be-particle ye-filler yi-≤6cm, kwaye ukuxinana okulula koomatshini kusetyenziswa ukuthintela ukonakala kwesakhiwo se-mesh core.

Ixesha leposi: Julayi-29-2025