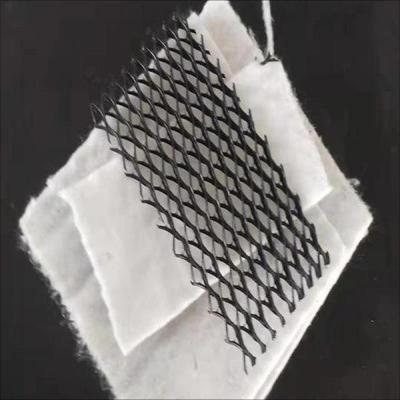

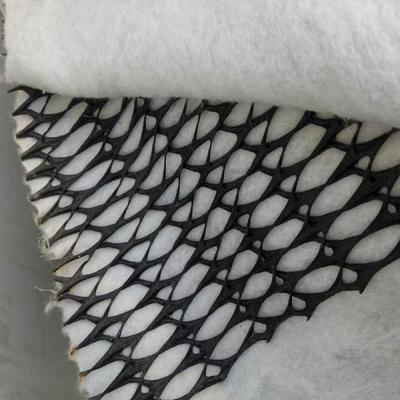

Three-dimensional geonet is a material commonly used in the fields of slope protection and ecological restoration. So, what are its construction methods?

1. Foundation preparation before construction

Geological survey and slope treatment should be carried out before construction. It is necessary to carry out three-dimensional laser scanning on the slope to clarify the slope ratio, geotechnical type and potential slip surface position.

2. Laying of three-dimensional geonet

1、Design of anchoring system

The anchoring system is the key to the cooperative stress between 3D geonet and slope. General use U Combined anchoring method of section steel nails and bamboo nails: the excavation width at the top of the slope is 30 cm、 Deep 20 cm Bury the end of the mesh into the trench and backfill it C20 Concrete; The slope area is distributed according to the plum blossom shape set Ф8mm Rebar anchors, spacing 1.0-1.5 m, Anchoring depth not less than 40 cm。

2、Lap joint process control

Transverse overlap width should ≥20cm, Longitudinal overlap should follow the principle of “press down”, that is, the upper mesh should cover the edge of the lower mesh 10-15 cm。 Double rows are adopted at the lap joints U Type nail fixation, nail distance is encrypted to 50 cm。

3、Construction of backfill overburden

The overburden should be completed in three times: the initial backfill 8-10 cm Thick and fine-grained soil shall be compacted by a small compactor; Slow-release fertilizer is mixed during secondary backfilling ( N:P:K=15:15:15)And water retaining agent, the mixing ratio is controlled at 3 ‰;The final covering layer thickness should reach 120% of the design value, Make sure the net bag is completely wrapped.

3. Construction of vegetation layer

1、Substrate ratio

The substrate layer should meet the triple requirements of “water retention-air permeability-nutrition”. The formula comprises 60% of humus soil, 20% of peat soil, 15% of organic fertilizer, 5% of binder and 0.5% of polyacrylamide water-retaining agent.

2、Technical parameters of spray seeding

When using hydraulic spraying machine for construction, the following parameters should be controlled: the distance between the nozzle and the slope surface is 0.8-1.2 m, Injection pressure 0.3-0.5 MPa, Seed density 25-30 g/m²。Slope ratio >1:0.75For steep slopes, 2% wood fiber should be added as the carrier material. In plateau and alpine regions, The mixed sowing scheme of cold-season grass species such as bluegrass and purple fescue with shrub seeds such as Caragana korshinskii and seabuckthorn can be used, which can quickly cover vegetation.

3、Maintenance management system

The maintenance cycle should last until the vegetation coverage rate reaches more than 80%. Spray 2-3 times a day in the initial stage, and the amount of water each time is limited to no runoff; Liquid fertilizer (concentration 0.5%) was topdressed once a month after the flat was formed. In terms of disease and pest control, biological preparations such as matrine and azadirachtin are preferentially used Agent to avoid the damage of soil microorganisms caused by chemicals.

4. Key points of quality control

Establish a three-level quality inspection system: check the tensile strength when materials enter the site ( ≥15kN/m)、 Mesh size deviation ( ±5%)And other parameters; During the construction process, a detection unit is set every 200 square meters, and the anchorage force is verified by pull-out test; 6 steps should be carried out during completion acceptance Monthly continuous monitoring, focusing on vegetation coverage, soil erosion modulus and other indicators.

Post time: Jun-18-2025