Three-dimensional composite drainage net is a commonly used drainage material in major projects. So, how is it produced?

1. Raw material selection and pretreatment

The core raw material of three-dimensional composite drainage net is high-density polyethylene (HDPE). Before production, HDPE raw materials must be strictly screened to ensure that its purity and quality meet production standards. Then the raw materials are pretreated by drying, preheating, etc. to eliminate internal moisture and impurities to lay a solid foundation for subsequent extrusion molding.

2. Extrusion molding process

Extrusion molding is a key link in the production of three-dimensional composite drainage nets. At this stage, the pretreated HDPE raw materials are sent to a professional extruder, and the raw materials are melted and extruded evenly through a high temperature and high pressure environment. During the extrusion process, a specially designed die head is used to accurately control the extrusion shape and size of the ribs to form a three-rib structure with a specific angle and spacing. These three ribs are arranged in a certain pattern to form a three-dimensional spatial structure. The middle rib is rigid and can form an efficient drainage channel, while the cross-arranged ribs play a supporting role, which can prevent the geotextile from being embedded in the drainage channel, ensuring stable and reliable drainage performance.

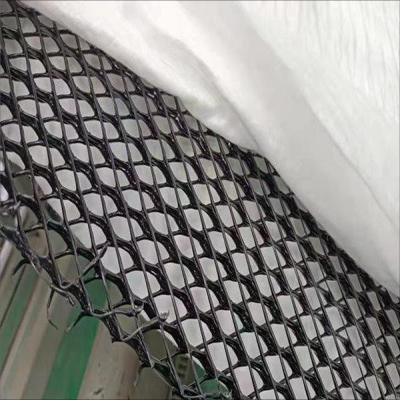

3. Composite geotextile bonding

The three-dimensional geonet core after extrusion molding must be composite bonded with the double-sided permeable geotextile. This process requires the adhesive to be evenly applied to the surface of the net core, and then the geotextile is accurately fitted, and the two are tightly combined by hot pressing or chemical bonding. The composite three-dimensional composite drainage net not only inherits the drainage performance of the geonet, but also integrates the anti-filtration and protection functions of the geotextile, forming a comprehensive performance of “anti-filtration-drainage-protection”.

4. Quality inspection and finished product packaging

The completed three-dimensional composite drainage net must undergo strict quality inspection, including appearance inspection, size measurement, performance testing and other links to ensure that each product meets industry standards and customer requirements. After passing the inspection, the drainage net is carefully packaged to prevent damage during transportation and storage. The selection of packaging materials should also focus on environmental protection and durability to ensure that the product can be delivered to customers safely and intact.

Post time: Jul-09-2025