Composite drainage network is a commonly used material in railways, highways, tunnels, municipal engineering and other fields. So, what is its shear resistance?

1. Structure and characteristics of composite drainage network

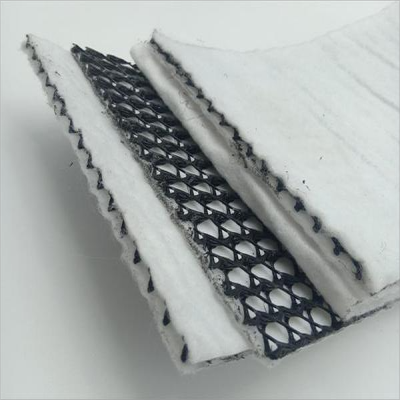

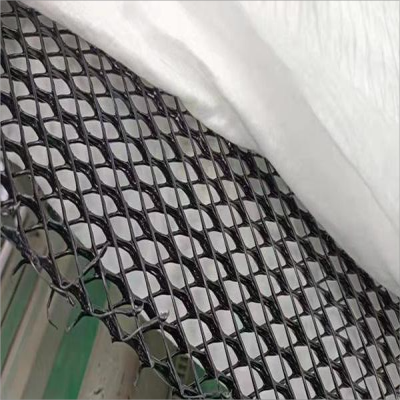

The composite drainage network is made of high-density polyethylene ( HDPE) As raw material, it is a drainage material with three layers of special structure processed by special extrusion molding process. The middle ribs have high rigidity and are arranged longitudinally to form a drainage channel, while the ribs arranged upper and lower cross form a support, which can prevent the geotextile from being embedded in the drainage channel. So, it maintains excellent drainage performance even under high loads.

2. The importance of shear resistance

1、Shear resistance refers to the ability of a material to resist shear failure. In civil engineering, drainage systems often need to withstand lateral pressure and shear forces from the soil. If the shear resistance of the drainage material is insufficient, it may be deformed or destroyed under the soil pressure, resulting in the failure of the drainage system and affecting the stability of the whole project.

2、The shear resistance of composite drainage network can be related to the stability and safety of drainage system. In railway subgrade, highway pavement and other projects, it has to bear the dual effects of vehicle load and soil pressure. If its shear resistance is insufficient, it may lead to deformation or rupture of the drainage network, which will affect the drainage effect and engineering stability.

3. Analysis of shear performance of composite drainage network

1、Material properties: The high-density polyethylene raw material used in the composite drainage network itself has high tensile strength and shear strength. Therefore, it can maintain good stability when bearing shear forces.

2、Structural design: The three-layer special structure of the composite drainage network also provides a strong guarantee for its shear resistance. The rigid arrangement of the middle ribs and the support of the upper and lower cross-arranged ribs allow the composite drainage network to evenly distribute stress when it bears shear force, and avoid damage caused by local stress concentration.

3、Construction technology: The construction technology of composite drainage network also has a certain impact on its shear resistance. During the laying process, it is necessary to ensure the close contact and good fixation between the drainage net and the soil, which can improve its shear stability. During the construction process, the drainage network should not be damaged or destroyed.

4. Measures to improve the shear resistance of composite drainage networks

1、Optimize material selection: Choosing raw materials with higher tensile strength and shear strength, such as reinforced polyethylene, can improve the shear resistance of the composite drainage network.

2、Improve structural design: By adjusting the arrangement of ribs, increasing the number of ribs or changing the shape of ribs, optimize the structural design of composite drainage network and improve its shear stability.

3、Strengthen construction process control: During the construction process, the construction quality and process parameters must be strictly controlled to ensure close contact and good fixation between the composite drainage network and the soil. Also avoid causing damage or damage to the drainage net.

It can be seen from the above that the shear resistance of the composite drainage network is one of the key factors to ensure the stability of the project. By optimizing material selection, improving structural design and strengthening construction process control, the shear resistance of composite drainage network can be improved, and its wide application and long-term stability in civil engineering field can be ensured.

Post time: Apr-24-2025