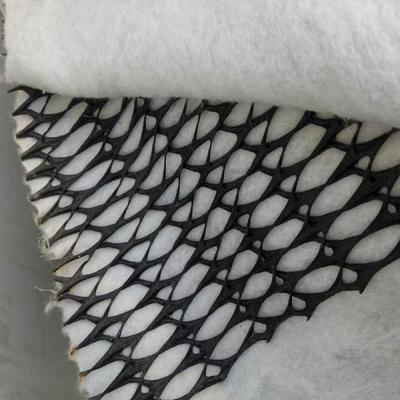

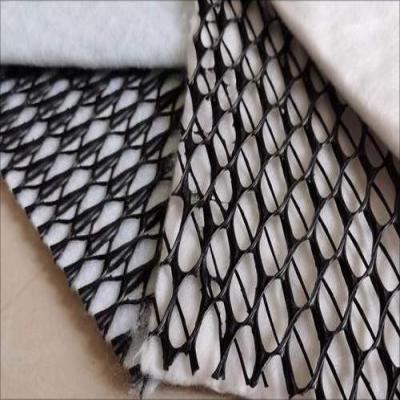

The three-dimensional composite drainage net is a commonly used drainage material in major projects. So, how should it be joined during construction?

1. Joint direction adjustment

When laying the three-dimensional composite drainage net, adjust the direction of the material roll to ensure that the length direction of the material roll is perpendicular to the main direction of the road or project. This adjustment allows the drainage net to maintain stable drainage performance when bearing loads, optimize the water flow path, and improve drainage efficiency. If the direction is improperly adjusted, it may lead to poor drainage or local water accumulation, affecting the project effect.

2. Material termination and overlap

The three-dimensional composite drainage net must be terminated, and the geotextiles on adjacent geonet cores must be overlapped along the direction of the material roll. When overlapping, ensure that the geotextile is flat and wrinkle-free, and the overlap length meets the design requirements. In general, the longitudinal overlap length is not less than 15cm, and the transverse overlap length is controlled within the range of 30-90cm. Insufficient overlap length may lead to insufficient strength at the joint, affecting the stability of the drainage net; while excessive overlap may increase material waste and construction difficulty.

3. Use of connectors

In joint processing, the selection and use of connectors are very important. Generally, white or yellow plastic buckles or polymer straps are used to connect the geonet cores of adjacent geotextile rolls. When connecting, use connectors to fix them at certain intervals (such as 30cm or 1m) along the length of the material roll. The connectors must have sufficient strength and durability to ensure the stability of the joints. If the connectors are used improperly, the joints may loosen or fall off, affecting the drainage effect of the drainage net.

4. Fixing of overlapping geotextiles

If the three-dimensional composite drainage net is laid between the foundation, base and subbase, the overlapping geotextiles must be fixed. Fixing methods include continuous wedge welding, flat head welding or stitching. When welding, ensure that the welds are neat, beautiful and free of slip welding and skipping; when stitching, flat head stitching or general stitching can be used to meet the minimum stitch length requirements. Fixing can enhance the strength and stability of the joints and prevent the geotextiles from being displaced or damaged during the stacking of fillers.

5. Special environment treatment

In special environments, such as when there are coarse-grained stones on the surface of the gravel foundation cushion, in order to prevent it from puncturing the anti-seepage geomembrane, a thin layer of mixed sand (3-5cm thick) should be spread and rolled on the surface of the gravel foundation cushion. The sand layer should completely cover the surface of the gravel foundation cushion, and there should be no gravel with a particle size of more than 4mm in the sand layer. When constructing in cold or high temperature environments, appropriate protective measures should be taken, such as heating connectors and adjusting construction time, to ensure that the quality of the joints is not affected by the environment.

As can be seen from the above, the joint treatment of the three-dimensional composite drainage net is a key link in the construction process, which is directly related to the drainage effect and overall stability of the drainage net. Following the specifications of joint direction adjustment, material termination and overlap, connector use, overlap geotextile fixation and special environment treatment can ensure the strength and stability of the joints and improve the drainage efficiency and service life of the drainage net.

Post time: Jun-24-2025