In tunnel engineering, the drainage system is very important. The three-dimensional composite drainage net is a commonly used drainage material in tunnel engineering. So, what are its applications in tunnels?

I. Technical characteristics of the three-dimensional composite drainage net

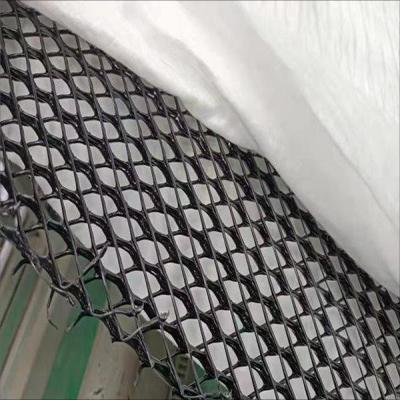

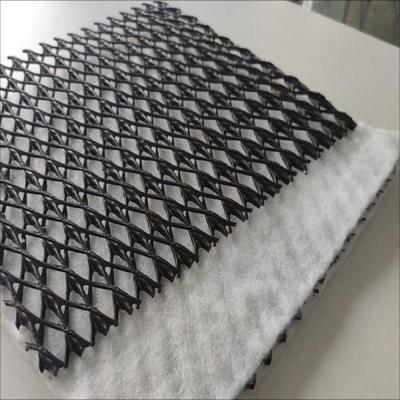

The three-dimensional composite drainage net is a composite of a three-dimensional plastic mesh core made of high-density polyethylene (HDPE) and a double-sided bonded permeable geotextile. Its core structure is a drainage channel formed by vertical ribs and upper and lower cross-support ribs to form a stable support system. Therefore, it has three major technical advantages:

1. Efficient drainage capacity: The permeability can reach 2500m/d, which is equivalent to the drainage effect of a 1-meter thick gravel layer, and can quickly drain the seepage in the tunnel.

2. High-pressure resistance: It can withstand a high-pressure load of 3000kPa for a long time, the mesh core thickness is 5-8mm, and the tensile strength is ≥36.5kN/m, ensuring stable operation under complex geological conditions.

3. Comprehensive protection function: It has anti-filtration, air permeability, and foundation reinforcement functions, forming an integrated protection system of “anti-filtration-drainage-protection”.

II. Four major application scenarios in tunnel engineering

1. Drainage layer behind lining

Water pressure is easily generated due to groundwater accumulation behind the tunnel lining, leading to leakage and even structural damage. The three-dimensional composite drainage net is laid between the lining and the surrounding rock to form a longitudinal drainage channel to guide the mountain seepage into the side ditch for discharge.

2. Inverted arch drainage system

The inverted arch is prone to frost heave deformation due to water accumulation. The three-dimensional composite drainage net is used in combination with the gravel layer to quickly drain groundwater. Its three-dimensional structure can block the rise of capillary water and prevent winter frost heave damage.

3. Side wall drainage layer

In a tunnel with weak surrounding rock, water seepage in the side wall can easily cause the support structure to become unstable. As a side wall drainage layer, the three-dimensional composite drainage net can not only drain the seepage water, but also limit the deformation of the surrounding rock through its high tensile strength. Test data shows that its shear strength is 40% higher than that of traditional materials, which can ensure the stability of the side wall.

4. Tunnel portal drainage transition layer

The tunnel portal is prone to collapse due to surface water infiltration. The three-dimensional composite drainage net is laid behind the tunnel portal lining to form a drainage transition layer to guide surface water into the drainage ditch. Its corrosion resistance can resist acidic groundwater erosion and ensure long-term stability.

III. Construction points and quality control

1. Laying direction control: The length direction of the material roll must be perpendicular to the tunnel axis to ensure that the drainage channel is consistent with the water flow direction.

2. Joint treatment: Use buckle or welding technology to fix, the overlap length is ≥15cm, and use U-shaped nails or polymer belts to connect every 0.3m.

3. Backfill protection: Backfilling should be completed within 48 hours after laying, the maximum particle size of the filler is ≤6cm, and light mechanical compaction is used to avoid damage to the mesh core structure.

Post time: Jul-29-2025