In engineering, the problem of silting has always been very important. Three dimensional composite drainage network It is a commonly used drainage material in major projects. So, can it prevent siltation and blockage?

1. Structural innovation

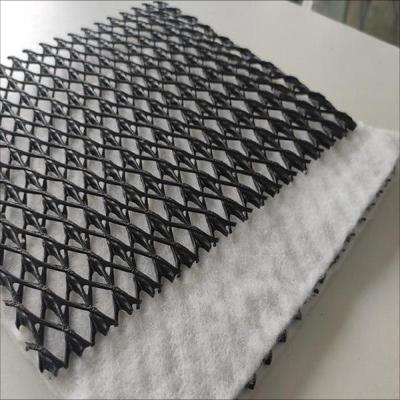

three-dimensional Composite drainage network Is composed of double-sided geotextile and three-dimensional geotextile core. The mesh core is made of high density polyethylene ( HDPE) The three-dimensional molding process forms a criss-crossing rib network, and its uniqueness is reflected in the following two aspects:

1、Gradient pore system: the vertical rib spacing of the mesh core is 10-20 mm, The top inclined rib and the bottom rib form a three-dimensional diversion channel, which is matched with the aperture gradient design of geotextile (upper layer 200 μm, Lower level 150 μm), Interceptable particle size greater than 0.3 mm Of particulate matter, Real Now “coarse filtration-fine filtration” graded filtration.

2、Anti-embedding design: mesh core rib thickness up to 4-8 mm, In 2000 kPa More than 90% of the original thickness can still be maintained under load, so as to avoid the geotextile being embedded in the mesh due to local compression. According to the engineering data of a landfill site, after 5 years of use, the drainage layer using this material will conduct water The rate attenuation rate is only 8%, which is far lower than the 35% of the traditional gravel layer.

2. Material properties

1、Chemical Stability: HDPE The mesh core is resistant to acid and alkali corrosion. In pH In a weak acid and weak base environment with a value of 4-10, its molecular structure stability retention rate exceeds 95%. Combined polyester Filament geotextile The UV-resistant coating can resist material aging caused by UV radiation.

2、Self-cleaning mechanism: surface roughness of mesh core Ra Value controlled at 3.2-6.3 μm Within the range, it can not only ensure the drainage efficiency, but also avoid biofilm adhesion caused by excessive smoothness.

3. Engineering practice

1、Landfill application: In a landfill with a daily processing capacity of 2,000 tons, the three-dimensional composite drainage network and HDPE The membrane constitutes a composite anti-seepage system. Its three-dimensional mesh core can withstand 1500 per day m³The impact load of leachate, combined with the backstop function of geotextile, can achieve percolation The liquid is discharged in one direction, which can prevent sludge from backflowing. After 3 years of operation, the pressure drop value of the drainage laminate is only 0.05 MPa, Well below the design limit of 0.2 MPa。

2、Road engineering application: In a freeway in a frozen soil area in northern China, it can be used as subgrade drainage layer, which can reduce the groundwater level by 1.2% by blocking the rise of capillary water m。 The lateral stiffness of its mesh core is 120 kN/m, It can limit the displacement of aggregate base layer and reduce the occurrence of reflective cracks. Monitoring shows that the incidence of road sections using this technology is reduced by 67% compared with traditional subgrade diseases, and the service life is extended to more than 20 years.

3、Tunnel engineering application: In a railway tunnel passing through water-rich stratum, a three-dimensional composite drainage network and grouting curtain are used together to form a waterproof system of “combining drainage and blocking”. Its core has a hydraulic conductivity of 2.5 ×10⁻³m/s, More traditional Drainage plate Improve 3 times, cooperate with geotechnical Cloth The filtration function can reduce the risk of clogging of the tunnel drainage system by 90%.

4. Maintenance strategy

1、Internet of Things monitoring: Optical fiber sensors are embedded in the drainage network to monitor parameters such as hydraulic conductivity, stress and strain in real time.

2. High pressure water jet curing: locally blocked areas, use 20-30 MPa High pressure water jet for directional dredging. The rib structure of the mesh core can bear the pressure without deformation, and the recovery rate of hydraulic conductivity after curing is over 95%.

Post time: Jun-14-2025